CS Series Tipping Hoists - A new generation of Edbro hydraulic tipping hoist equipment to suit rigid truck and trailer tippers worldwide.

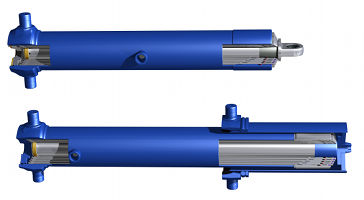

The CS range of cylinders is the lightest and most durable range of telescopic cylinders in the world, providing a true "fit and forget" solution to tipping applications.

Extensive range of lightweight, durable cylinders with a variety of mounting options and Edbro's winning technology enabling reduced tipping times for increased lift capacities and higher payloads.

Benefits:

- Increased Payloads – The world’s lightest tipping cylinder provides increased payload and so increased operating profit.

- Increased Lift Capacity – Advanced design and production engineering techniques, including laser welding, provide increased lift capacity.

- Faster Tipping Speeds – One piece construction and increased tube contact faces enable faster tipping speeds.

- “Fit and Forget” Cylinder – Innovative design features combined with the highest quality materials and a unique 3-piece sealing system provide the “Fit and Forget” promise.

Features and Technology:

- Edbro invests heavily in research and development to ensure that the C Series cylinders evolve to meet the ever-changing needs of customers.

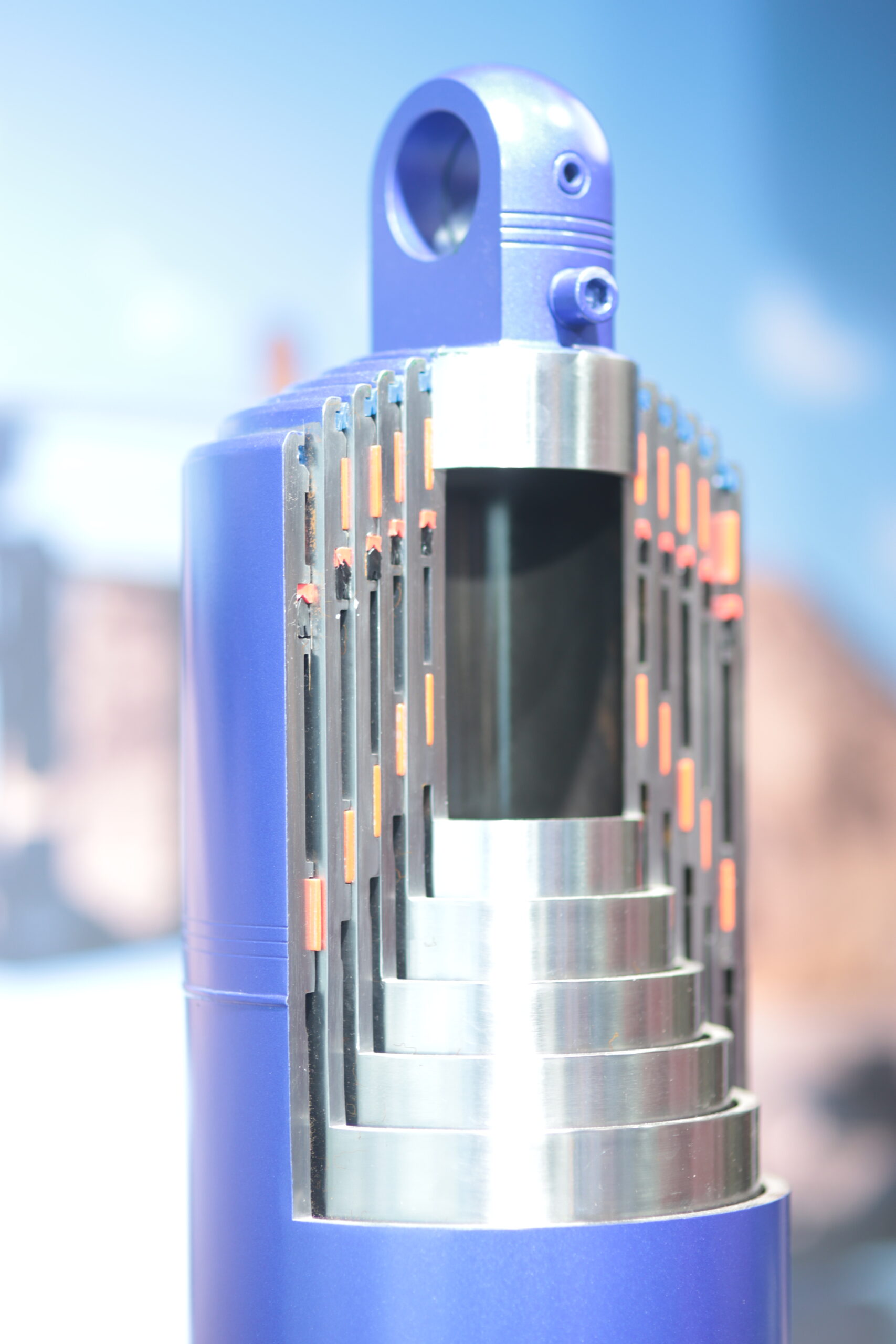

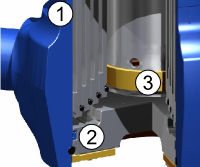

- Double lip wiper seal ensures efficient lubrication of each tube and prevents contamination of the cylinder.

- Unique 5-point sealing system reduces friction for years of smooth, trouble-free operation, provides long life and ensures easy servicing.

- Wear rings made from non-metallic, acetal material provide low friction and long service life.

- Cast iron sliders reduce the risk of scoring and damage due to side load.

- Thanks to advanced manufacturing techniques and high-quality materials, these tipping cylinders are proven to increase payload, offer faster tipping speeds and last longer.

Model Range

Models in the CX Series are available with lift capacities from 10 to 32 tonnes and are designed for rigid trucks with 15 to 36 tonne G.V.W.

| Model code | Nominal Truck G.V.W.(t) | Hoist Stroke (mm)* | Nominal Lift Capacity (t) | Nominal Body Length (m) | Average Kit Weight Incl. oil (kg) |

|---|---|---|---|---|---|

| CX07 | 7.5 – 15 | 2,130 | 07 – 11 | 3.0 | 165 |

| 2,355 | 3.25 | ||||

| 2,595 | 3.5 | ||||

| 2,895 | 3.5 | ||||

| 3,195 | 4.25 | ||||

| CX10 | 15 | 3,059 | 10 – 13 | 4.0 | 212 |

| 3,359 | 4.3 | ||||

| CX11 | 18 | 3,271 | 12 – 15 | 4.25 | 289 |

| 3,871 | 5.0 | ||||

| 4,271 | 5.5 | ||||

| CX11 | 22 | 3,344 | 16 | 4.5 | 289 |

| 3,644 | 5.0 | ||||

| 3,944 | 5.25 | ||||

| CX13 | 26 | 3,841 | 19 – 24 | 5.0 | 442 |

| 4,241 | 5.5 | ||||

| 4,641 | 6.0 | ||||

| CX14 | 32 | 5041 | 22 – 25 | 6.5 | 477 |

| CX15 | 32 – 36 | 4,606 | 29-32 | 5.75 | 535 |

| 5,006 | 6.50 | ||||

| 5,606 | 7.0 |

Actual kit weight relates to complete hoist kit including PTO/pump. Actual weights vary according to installation

* Further strokes available on request

Hydraulic Kit Solutions

Hydraulic kit solutions available to optimise cylinder performance. For full details check out the Hydraulic Kit Solutions page.