Benefits

Lighter

Increased Payloads

The world’s lightest tipping cylinders providing increased payload and so increased operating profits.

Faster

Faster Tipping Speeds

One-piece tube construction and increased tube contact faces allow faster tipping speeds.

Stronger

Increased Lift & Side Load Capacity

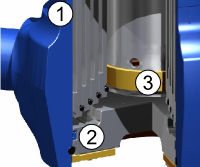

Advanced design and production engineering techniques, including laser welding, provide increased lift capacity and side load resistance. Base tube head section increased by as much as 53%.

Features

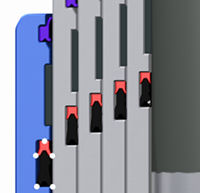

- Double lip wiper seal ensures efficient lubrication of each tube and prevents contamination of the cylinder.

- Unique 5 point sealing system reduces friction for years of smooth, trouble-free operation.

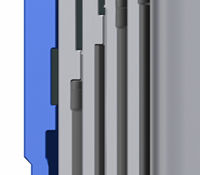

- Wear rings made from non-metallic, acetal material provide low friction and long service life.

- One-piece tubes with large stop contact faces provide optimum durability for long life and reduced maintenance.

- Friction welded tube assembly increases strength and fatigue life.

- Unique clip and seal arrangement provides long life and ensures easy servicing.

- Brass slider reduces risk of scoring and damage due to side load.