World-Leading

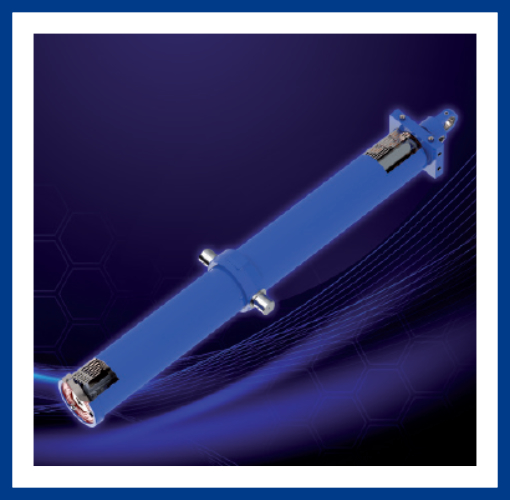

hydraulic cylinders

For on-road, off-road and recycling and waste applications.

Edbro is a global leader in vehicle-mounted hydraulic systems, offering industry-leading solutions including front-end cylinders, underbody cylinders, ejector cylinders, waste handling equipment, custom hydraulic kits for tipper trucks and commercial vehicles.

Since 1916, Edbro has pioneered hydraulic innovation starting with the world’s first engine-powered lifting system, developed by founder Maurice Edwards. Today, our products continue to set the standard for performance, reliability, and innovation in tipping gear.

Edbro offers a comprehensive range of hydraulic components, including oil tanks, pumps, pipes, valves, and more all engineered for optimal compatibility and performance. This enables us to deliver fully integrated hydraulic system solutions tailored to each customer’s vehicle specification and operational needs. Choose Edbro for a one-stop solution to streamline installation, reduce downtime, and ensure long-term reliability.